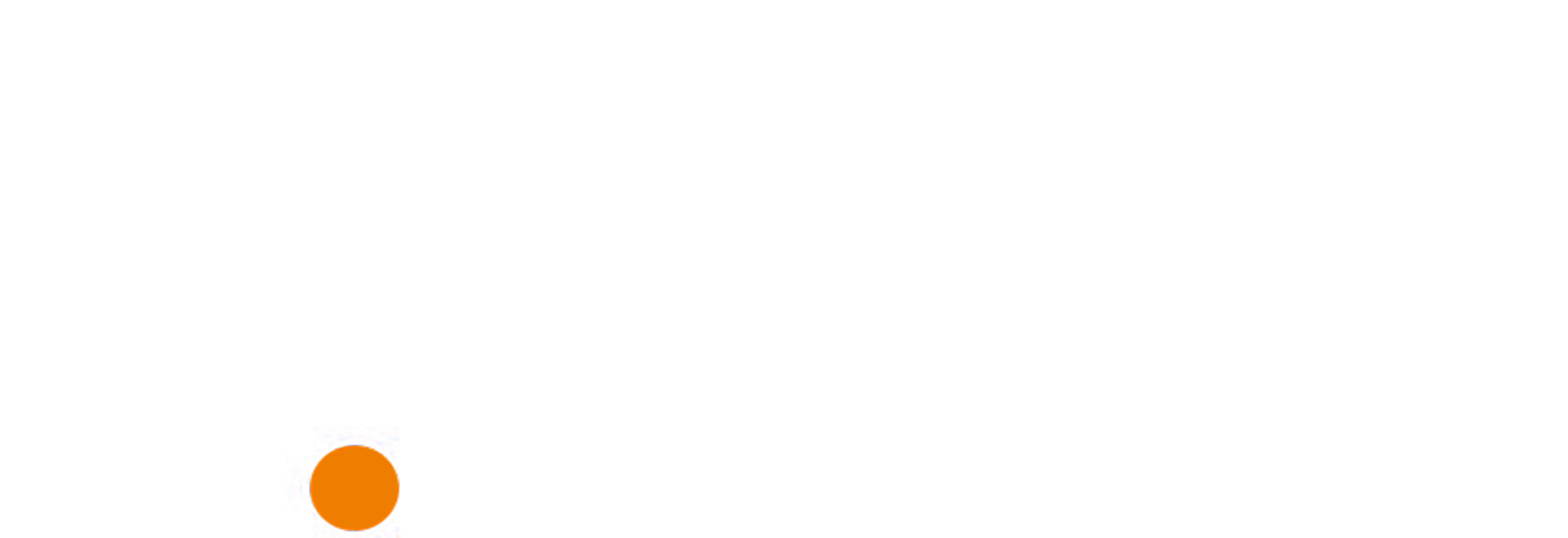

Single-Axis NC-Dividing Unit RWNC

The single-axis NC-Dividing Unit RWNC has been specially developed for horizontal and vertical use on machine tools and machining centres. Its available with center heights of 75, 100, 125, 160, 220, 300, 380 and 400 mm. The hydraulic clamping of the indexing spindle allows high power in processing. You can use direct or indirect measuring systems.

Main Characteristics

Excellently Perfomance and Accuracy Datas

- High indexing spindle speed for minimized non productive times

- High load capacity for the treatment of heavy workpieces

- Extensive automation features

- Exceptionally exact geometry datas within the µ-range

- Dividing accuracy up to the range of one tenth of a second of arc

Surface coated gear box

- High corrosion resistance

- Durability and high availability

- Function and appearance remain over years

Solid motor cover made of stainless steel

- With internal fixing

- Much more solid in comparison to motor covers made of other materials

- Sealed design by sealing on the planar side

Sunked and flushed covers and closures on the gear box

- Appealing appearance

- Uninterrupted flow of chips and coolants

- No ingoing gaps

Attractive Design

- Suitable to current machines of well known manufacturers

Advantages

CNC-dividing units from the Hofmann RWNCseries are especially characterised by a reliable, robust and solid design. The customer gets a reliable and individual solution according to the particular applicaton in combination with extraordinary high accuracy

values.

The eccentric adjustable worm gear consits of a case hardened worm shaft and a worm wheel made of an extraordinary wear resistant bronze alloy.

A significant low current consumption in comparison to torque drives will be achieved by a low friction and a low backlesh run in combination with a high perfomance lubricant.

The sophisticated design ensures a failure free operation at everytime for years and gives hereby an important input for the efficiency of your company.

At A Glance

- Highest precision by manufacture and quality control in our own company

- Low energy consuption in comparison to torque drives

- High rigidity by heavy duty axial-/radial ball bearings and worm drive with big diameter

- Eight different design sizes available

- Backlash of worm drive easily adjustable

- Wide variety of motor installations

- Wide range of accessories available

- Attractive price-performance ratio

- Easy to service

- Special designs for customer specific applications easy realizable

- Compact construction

- Matured construction

- Long lasting and modular extendible

- Fast customer service

Sizes

An almost full and complete range of individual customer wishes will be covered by our modular design, which offers a large variability by currently eight different sizes and a wide

range of different motor mounting variations.

Designs

- Centre heights: 75, 100, 125, 160, 220, 300, 380, 400 (mm)

- Indirect measurement systems

- Direct measurement systems for increased indexing accuracy

- Mounting of all motor typs according to customers request

- different versions of indexing spindle:

- Cylindrical bore (standard)

- Morse taper MT

- Short taper ST

- Steep taper

- Hollow shaft cone HSK

- Customer spindle solutions

- Increased circular or axial runouts

- Installation of rotary distributor for hydraulic or pneumatic possible 2-, 4-, 6-fold

- multi-spindle versions

- Multi-spindle dividing units are available with 2, 3, 4, 5 and 6 indexing spindles.

- Centre heights and axis distances are adaptable according to customers requirements.

- Depending on the axes distance, the indexing spindles are in a common housing or several one axes dividing units will be coupled on a base plate.

Accessories

- Tailstocks

- Supports

- Three- and Four Jaw Chucks (manual + hydraulic)

- Face Plats in various diameters and versions

- Interfaces | Power Supply

- Controls

- Hydraulic Units | Pressure Converters

- Collet Chucks

- Spindle Holders

- Clamping Bridges

- Motors

- Direct Heidenhain Measurement Systems

- Further accessories available upon request.