Customer and Special Solutions

For special use cases when standard dividing units cannot be used or reach their limits, we develop special solutions – customized in accordance to your tasks and maschine technology.

Special features such as special mountings of the servomotor, connections to machine-side power supply or number and design of the workpiece holders are defined and implemented in close contact with the customer. In contrast to specified modular systems, there are virtually no limitation in design and construction.

With the Extension of a Hofmann additional axis from the product segment customer and special solutions, productivity of machining centers from different manufacturers can be increased efficiently.

Special Features

- Design of a Hofmann special solution will be done in close dialogue with the customer

- Almost no limitation in design and construction

- Solid and rigid construction to achieve high cutting data

- Use of proven and reliable components from the standard Hofmann dividing units

Purpose/Applications

- Production of large quantities

- Saving of set up- and tool change times

- Use on special machines

- Processing outside of defined standard solutions

- Retrofitting, flexibility and improved performance of existing machine concepts

Examples of Use

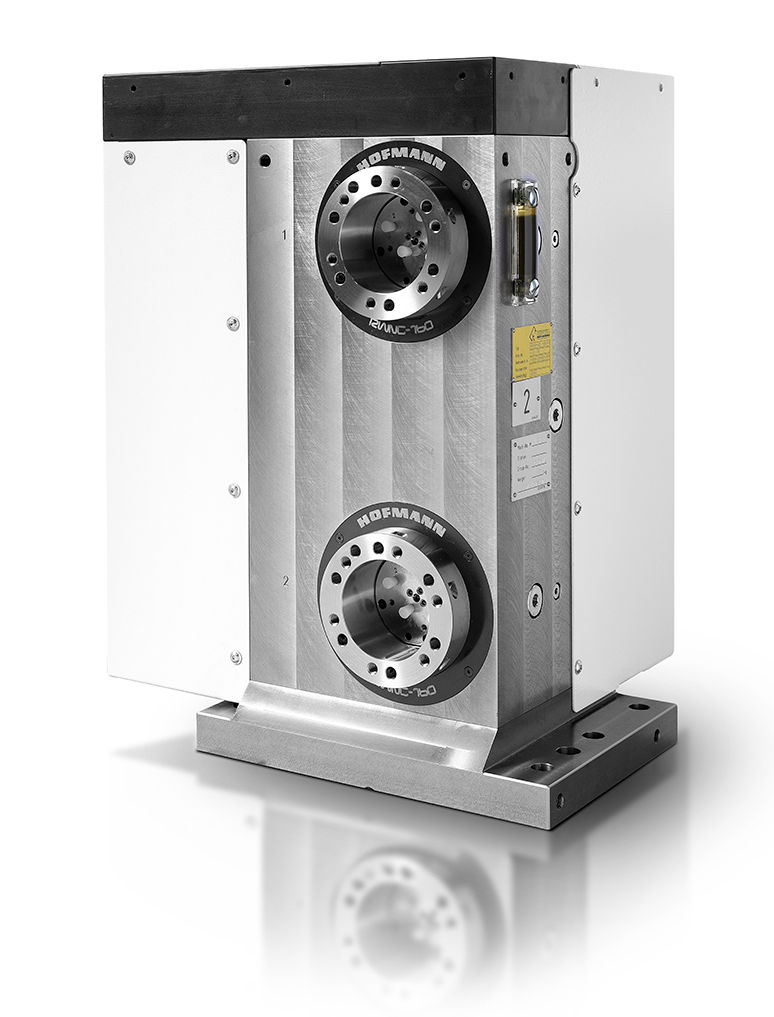

Hofmann RWNC-160/2 dividing unit with mounted two vertically indexing spindles in one housing. The indexing spindles are equipped each with a 4-fold rotary transmission to supply the hydraulic pressure for the clamping devices. The hydraulic pressure are supplied central by the palett of the machine and the base plate of the dividing center. Furthermore the indexing spindle have a Heidenhain-Decoder as direct meassuring system, for the exact positioning of the workpiece.

The technical construction of the dividing center was established in the range of our customized solutions in close collaboration with our customers – as usual.

Delivery of a total of eight RWNC-300 LD axes for four Heller MC 16 machining centers of an automotive supplier. The machining center has a pallet changer and thus two pallet locations, which are located alternately in the workroom or on the retrofit station. For the production of aluminum castings, this had to be retrofitted with an additional rotary axis with hydraulic clamping device. With the addition of two axes per machine, not only was it possible to process a major order, but also significantly upgrade the machines that have been in use for several years.

Another project is the combination of a six-spindle RWNC-160/6 axis with an MC 5000 machining center from Heller. This axle has succeeded in drastically reducing tool change times. When working on identical parts, the changeover time could be reduced by 40% since six workpieces can be clamped in parallel. With this axis, it is also possible to use a wide variety of clamping systems. This makes this special solution a flexible system.

More examples you can find in our category Success Stories.