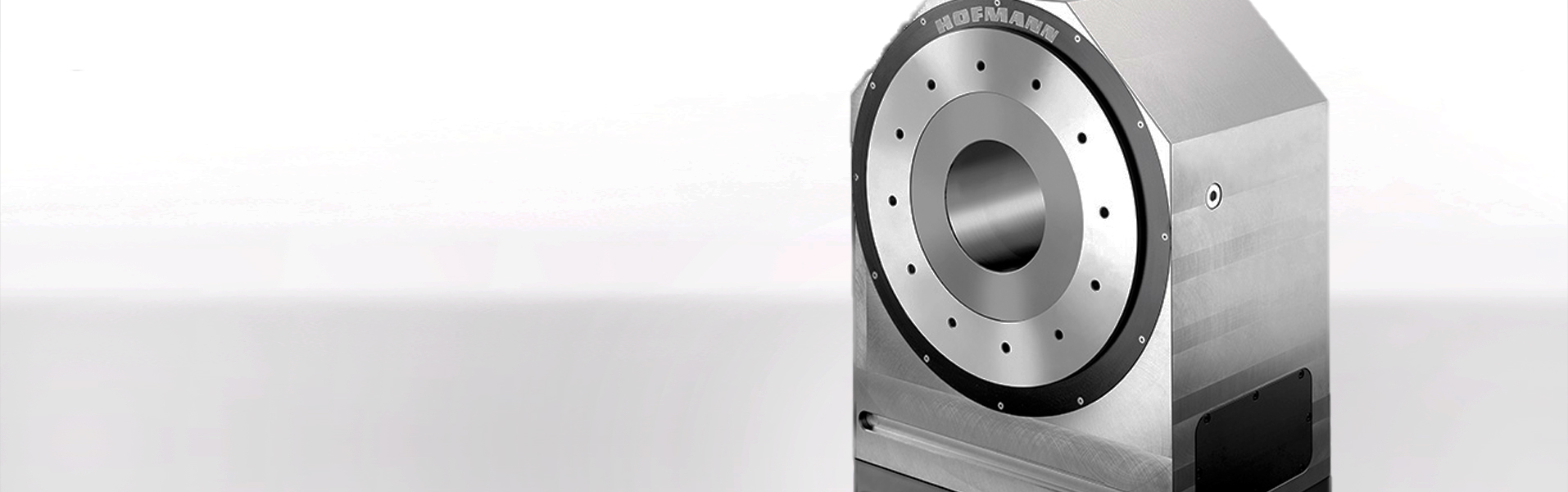

NC-Dividing Unit HD with Torque

The NC-Dividing Unit HD has a direct drive. The torque motor is directly connected to the indexing spindle without a reduction stage. This enables the indexing spindle to achieve high speeds over a longer period of time.

The NC-dividing unit can be used with a vertical or horizontal turning axis. Center heights of 200, 250, 350 and 400 mm are possible. The spring-loaded safety clamping of the sub-spindle allows high machining forces. The indexing spindle allows jigs to be built-on quickly. The dividing unit HD is connected as a 4th axis with a direct drive to the CNC-control of the machine.

Main Characteristics

- Direct drive for use as a 4th axis on a machining centre.

- high precision due to in-house production and quality control

- housing is applicable for horizontal and vertical turning axis

- Absolutely free of clearance thanks to the torque motor

- High dynamic and allmost free from wear for stable quality

- High speed and torque allows continous operations

- Various direct measuring systems compliant with the precision requirement deliverable

- High rigidity by using an axial-radial angular contact ball bearing

- Pneumatic safety clamping:

- Declamping at 6 bar

- Clamping with 0 bar by means of a spring assembly (emergency stop)

- Clamping force doubled with spring assembly and 6 bar at the opposite site

- Wide range of accessories available

The ideal solution for every application

- Horizontal or vertical turning axis.

- Center heights of 200, 250 and 350 are available.

- A spring-loaded safety clamp on the indexing spindle allows high machining forces.

- The indexing spindle allows jigs to be built-on quickly.

Swivelling Dividing Units HDS

Swivelled dividing units HDS are using dividing units from HD series as rotating and tilting axis. The modular design allows an easy adaptation to customer requirements.

Multi spindle versions, hydraulically clamped supports and direct measuring systems are available as well.

Special Versions HD-HDS

- Outside dimensions of dividing unit in a cubic or round housing according to the machine interior

- Drive design on rotation speed or high torque

- Drive with torque motors according to customers specification

- Combination of worm drive and torque motor at tilting dividing unit

- Accessories like dividing units RWNC

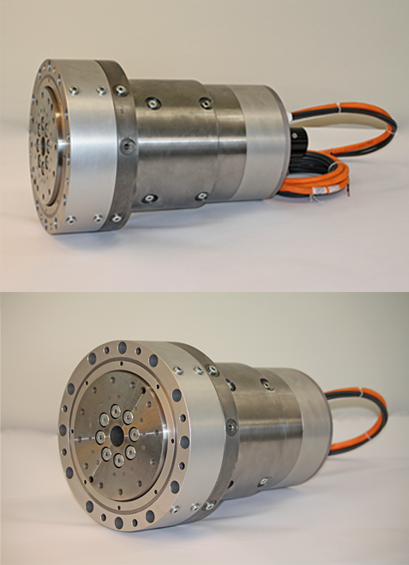

HD-160 Mounting Axis with Direct Drive

The special feature of these axes is the housing, which was designed as a round, flange-like housing for installation in machine tables.

Basically, the built-in rotary axes of the HD-MA series offer the same functionality as the rotary tables of the HD series, which are mounted as additional rotary axes on machine tables of machining centers.

The HD-MA series is characterized by the following features:

- Connection dimensions for installation in the machine table according to customer requirements

- Design of the direct drive according to customer requirements

- High speeds compared to rotary tables with gears

- Space-saving design

- Easy integration and assembly in machine tools or plants possible

- With or without water cooling, depending on the application

- Fast exchangeability in case of service

Hofmann installation axes are always designed and supplied according to customer requirements. Decisive factors here are the installation situation and the required performance data.