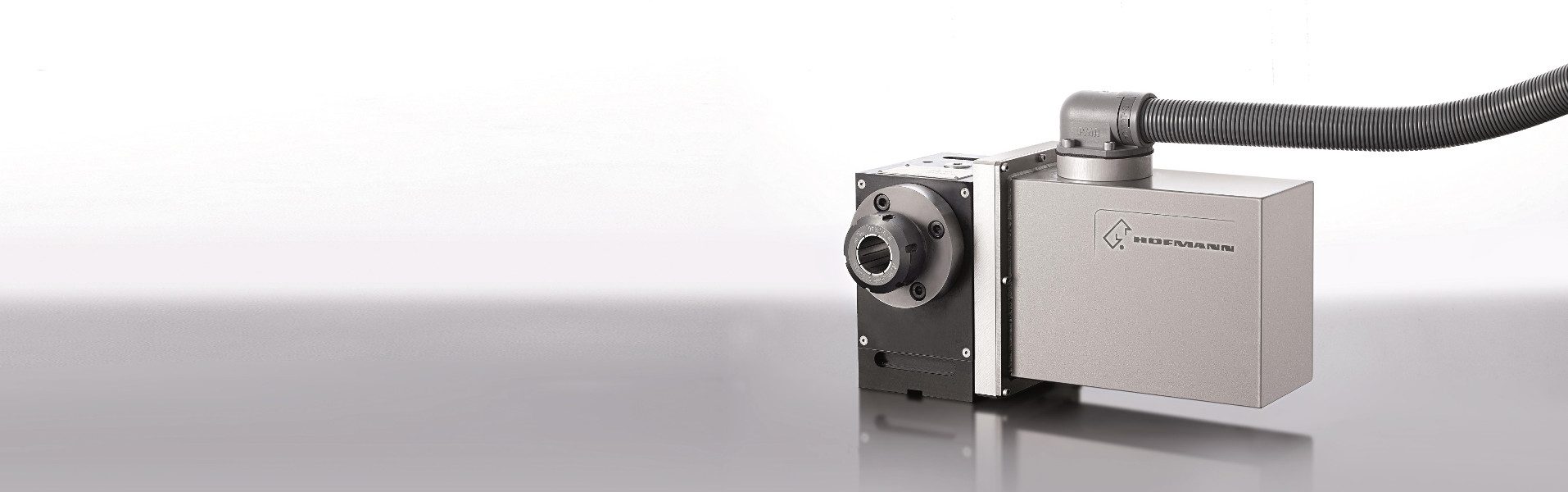

The half-universal Dividing Head HTH with manual turning and swivel axis is designed for indirect and direct positioning of workpieces on machine tools. It has a center height of 100 mm.With a suitable base you can reach center heights of 125, 160 and 200 mm.

MAIN CHARACTERISTICS

- Center height of 100 mm for direct and indirect positioning of workpieces on machine tools.

- The worm gear is set to a low amount of backlash

and enables the turning axis to be positioned manually with an indexing plate device. The standard indexing plate has 10 indexing circles on each side with the hole counts 13, 15, 16, 17, 18, 19, 20, 21, 23, 24, 27, 29, 31, 33, 37, 39, 41, 43, 47 and 49. - Eccentric worm shaft bearing to compensate the backlash in the worm gear, or for swivelling out for

direct indexing work. - If the worm gear is swivelled out, direct indexing can be carried out at the indexing spindle with direct indexing plate and notch lever. The direct indexing plate is located protected at the rear end of the indexing spindle, and has 24 notches for indexing 2, 3, 4, 6, 8, 12 and 24 positions.

- Indexing spindle with MT (Morse taper) hole and external short taper to enable workpiece clamping systems to be replaced quickly.

- Compact, space-saving design with high rigidity in both axes.

- The turning and tilting axes are clamped to achieve a high machining performance. The turning axis is clamped by a manually operated hydraulic clamp and the swivel axis to both tension brackets at the

trunnions. - Housing parts are painted with structured coating RAL 7035 Light Grey.

TURNING AXIS INDEXING CAN BE CARRIEDOUT WITH

- Indirect indexing using a worm drive with graduating drum and vernier scale

- Indirect indexing using a worm drive with dividing plate indexing device

- Direct indexing with swivelled-out worm drive using replaceable direct indexing discs

ACCESSORIES

- Rigid, manually operated tailstocks, also with MT tailstock sleeve

- Moveable tailstock with fixed tailstock centre

- Manual three-jaw chuck with flange to be attached to the indexing spindle

- Manual collet chuck with through bore or MK retainers to be attached to the indexing spindle for standard collets

- Centre and carrier to be attached to the indexing spindle

- Steady rest for longer workpieces

- Raiser plate set for dividing head and tailstock for increasing the centre height

- Additional direct indexing plates with 2 to 36 notches; can be replaced with the standard direct indexing plate

- The additional direct indexing plate for the indexing plate device has ten indexing circles on each side with the hole numbers 51, 53, 57, 59, 61, 63, 67, 69, 71, 73, 77, 79, 81, 83, 87, 89, 91, 93, 97 and 99.

- Hand wheel with micrometer dial, also suitable for uneven indexing, can be replaced by the hole plate attachment